THREAD ROLLING TOOLS

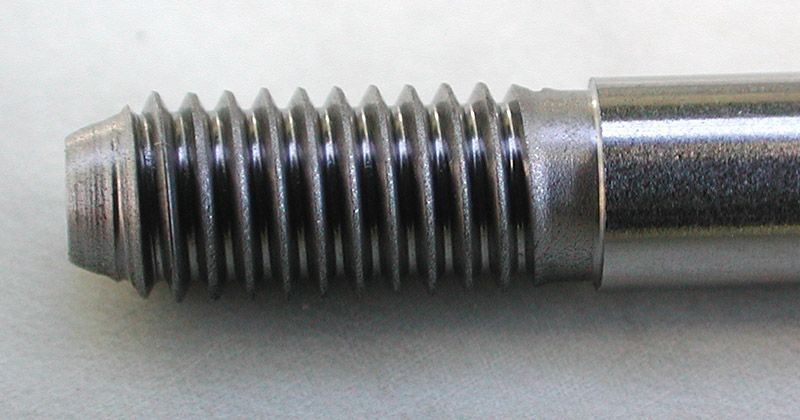

Thread rolling dies

Used on the bar turning automatics producing watch screws, spectacle screws, attachment screws, etc.

Available in adjustable or non adjustable types.

Main advantages

Better thread quality

High machining regularity

Increased thread resistance

Reduced breaking points

Better surface values on the thread flanks and on the thread root

Made in Switzerland

Thread rolling dies, adjustable

-

These rolling dies are recommended for machining small and medium workpiece batches.

-

The diameter on the thread flank can be adjusted by means of the nut of type R die holders.

-

The outside diameter is adjusted by modifying the turning diameter before thread rolling. Take care that the thread is not full and that a slight flat remains on top of the profile.

-

The use of these dies is very economical thanks to their adjustment possibilities.

Die holders, adjustable

-

The die holders, type R, permit to mount our adjustable rolling dies on all types of automatics.

-

The assembly on the machine will be effected either with a clamping collet or directly into the collet housing with the help of a clamping cone.

Die holders, adjustable, with compensating system

-

The die holders with compensating system are needed on machines with fixed headstock and on CNC machines.

Thread rolling dies, non adjustable

-

Recommended for large batches of workpieces.

-

Indicate tolerance and material at order.

-

The outside diameter is adjusted by changing the turning diameter.

Die holders, non adjustable

-

The die holders, type NR, permit to mount our non-adjustable rolling dies on all types of automatics.

-

The assembly on the machine will be effected either with a clamping collet or directly into the collet housing with the help of a clamping cone.

Die holders, non adjustable, with compensating system

-

The die holders with compensating system are needed on machines with fixed headstock and on CNC machines.

Thread rolling on CNC machines

If the threads are produced on a CNC machine, the use of the die holder with compensating system is necessary. The function “rigid tapping” don’t suit the rolling.

Turning diameter before thread rolling

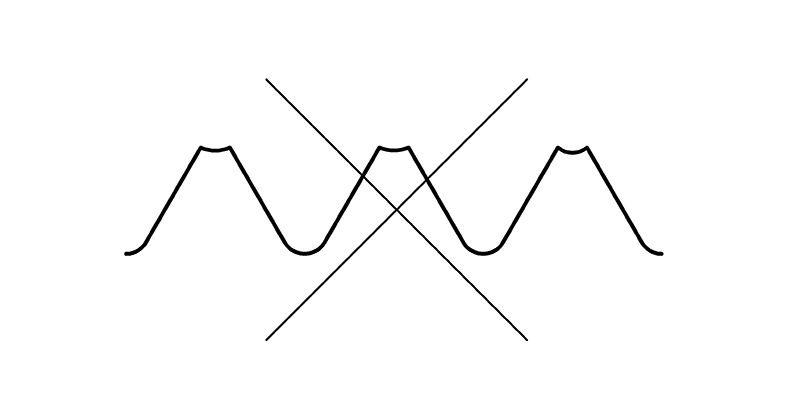

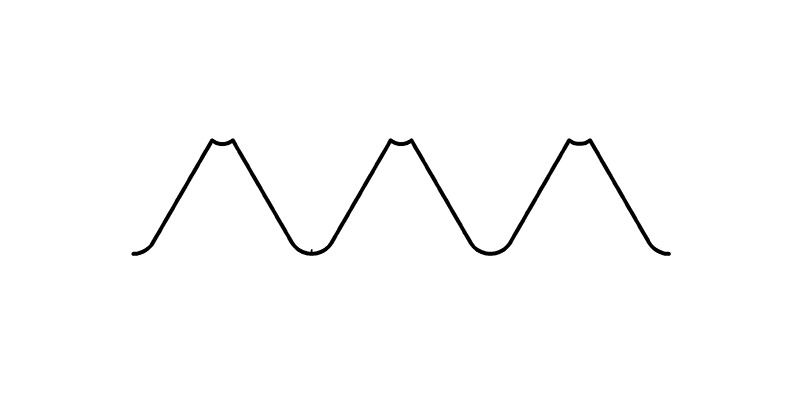

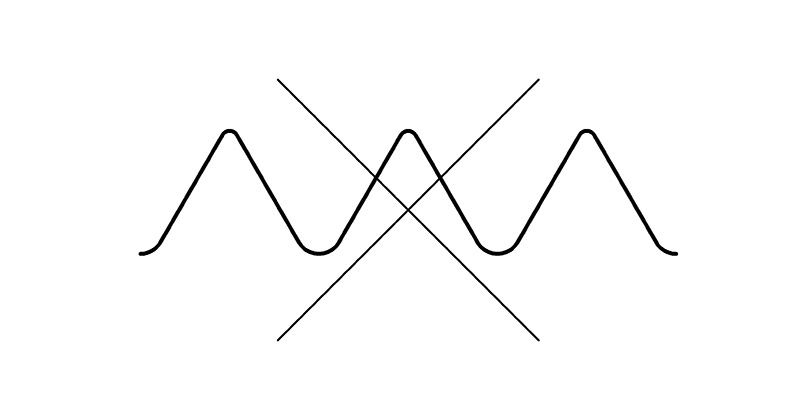

It corresponds to the diameter on flank, less a few hundredths. The final adjustment is effected according to the obtained profile, as per sketch below:

Technical documentation

Here you can find all our operating instructions in different languages

On customer’s request

Special profiles, cleared-off pivots to let the screw head pass through.

Important choice of other thread rolling dies with the following capacities:

Thread dia.: from 0.35 to 14.00 mm – Pitch: from 0.09 to 1.25 mm 120 TPI to 24 TPI

Usually, all the rolling dies are available for L.H. threading (type L).